Prototypes and pre-series

MTorres has a large number of technologies related to composite materials that make us the ideal partner for the manufacturing needs of prototypes and pre-series composite materials through a completely industrial process.

Monocoque structure prototype in manufacturing process within the Torreswing project

MTorres offers its clients capabilities in the complete manufacturing process of composite materials for the development of industrial prototype or pre-series components, adjusting the automation levels to the requirements of each specific project:

- Development of complete manufacturing and industrialization projects for composite components

- Manual and automatic lamination in dry room of preimpregnated, dry, thermoplastic materials,…

- Design and development of material formats

- Design, manufacture and set-up of molds and tools

- Resin infusion processes

- Oven for curing components up to 50m x 4.5m x 2.5m and autoclave curing management through third parties

- Advanced machining and surface finishing for parts up to 40m x 4.5m x 2.5m

- Quality and inspection

Lamination

Automatic wrapping head on a gantry-type structure inside a dry room with controlled environmental conditions

Automatic wrapping head on robotic platform

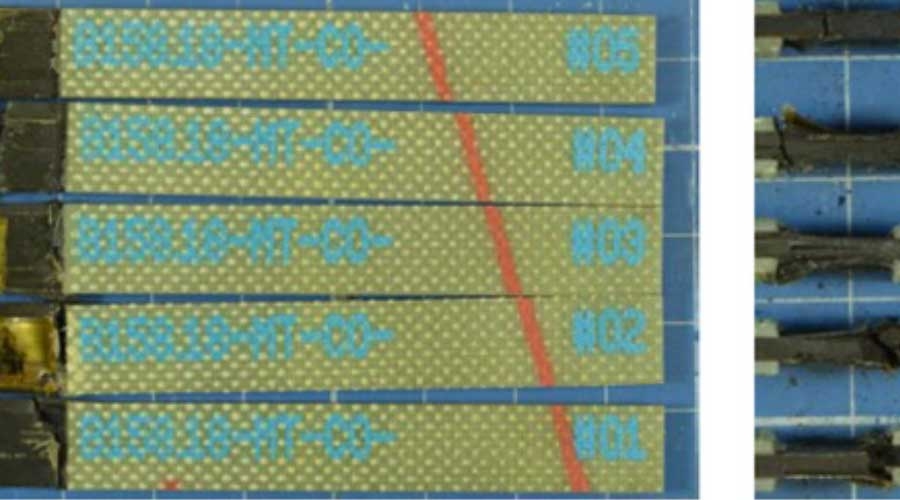

Materials

MTorres offers the development of dry fiber material configurations adaptable to the needs of each specific project

MTorres has extensive experience in the manufacture of test pieces and test management by certified centers, along with their analysis and the generation of admissible designs.

MTorres is in charge of the management of specific analyzes for different materials, the analysis of results and the identification of optimal solutions for your project.

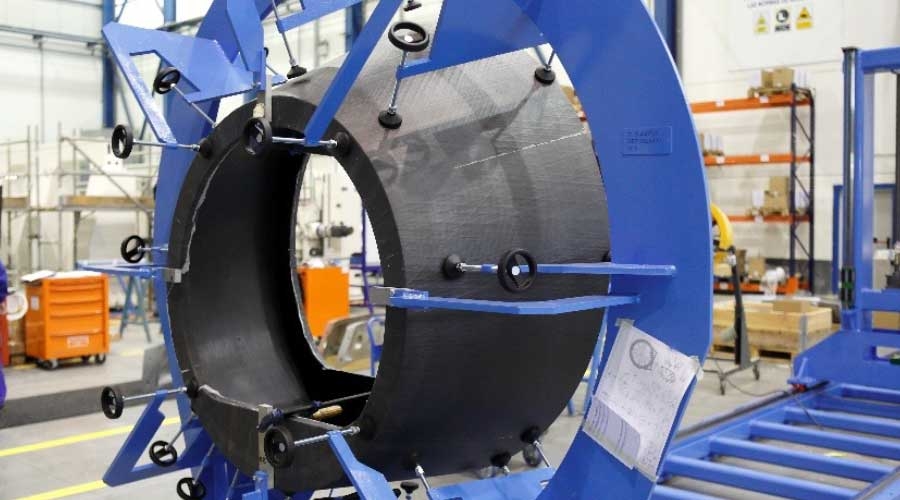

Design, manufacture and commissioning of molds and tools

Structural response analysis of a wind turbine blade skin mold

Mold and mold turning system

Development of a semi-automatic tool for gluing components in composite material

Development of an assembly dock for the automated assembly of wind turbine blades

Manufacturing of curing molds for metal composite material (invar, steel and aluminum)

Detail of the mold for manufacturing wings with integrated leading edge developed by MTorres

Development of carbon fiber molds, integrating design, model making and final mold manufacturing

Fiberglass mold manufacturing for complex geometries

Manufacture of foam molds

Resin infusion processes

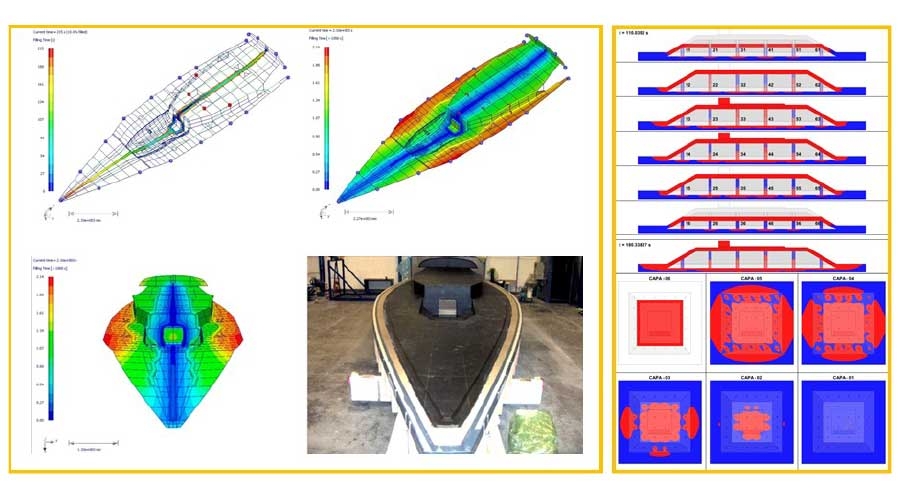

Simulation of infusion processes

Preparation of the infusion process of a structural wing box within the IIAMS project

Resin infusion in large parts

Development of the infusion process

Curing

Oven for curing components up to 50m x 4.5m x 2.5m

Inside view of the curing oven

Mobile curing station developed for the curing of parts within the IIAMS project

Machining

Advanced machining and surface finishing capabilities for parts up to 40m x 4.5m x 2.5m